The Boro’ Foundry work with ADI Treatments Ltd to produce Unimog component for Atkinson Vos

Component

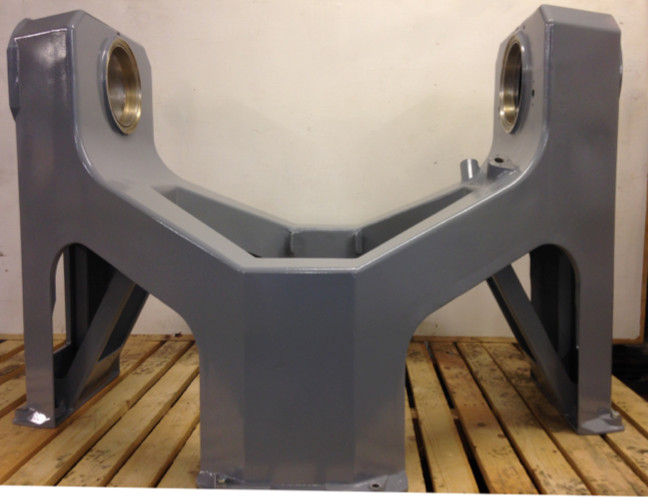

Unimog 3 Point Linkage Power Lift Arm, 54kg.

Application

Agricultural, Forest and Rail sector.

Metal

ADI – grade EN 1564 900-8.

Process

3D printing and sand casting, alkaline phenolic, floor moulding.

Project Information

Conversion from steel fabrication with 9 lasercut pieces to cast component in ADI. The design was inelegant, prone to torsional failure and bending. The project was to resign and optimise the geometry, increasing reliability for the same part cost.

Challenges and Achievements

- Steel fabrication with 9 laser-cut parts, prone to failure.

- Reduced process steps – 1 part to replace 9

- Cast design was 4x stronger in critical areas.

- Use of ADI (giving lighter part weight compared with cast steel equivalent).

- Design optimisation achieved giving greater reliability and cleaner geometry.

- Greater flexibility of supply for customer through casting.

- Client company logo can be cast-on.