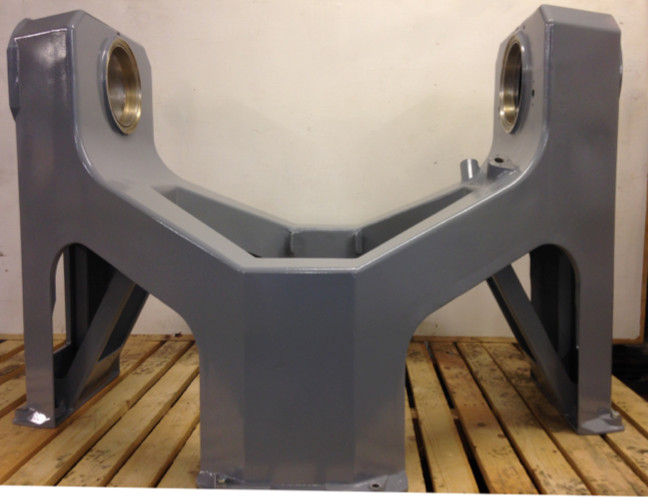

Peel Jones Copper Products undertook a redesign to improve a critical component used as the nozzle to blast air into the furnace during steel production.

Component

Blast Furnace Tuyere, weighing 229 kg

Alloy

- Copper BS6017

Customer Requirements

- Ability to withstand a very aggressive environment within a blast furnace, utilising complex internal cooling channels.

Method

- Sand casting and CNC tooling

- CAD and casting simulation to optimise design and casting method

Outcome

- Optimised design through fluid flow and heat transfer modelling.

- Tighter tolerances in wall thickness achieved.

- Productivity increased by 100% (through reduced mould and core variability).

- 16% reduction in scrap and yield increased by 17%.

- Final component weight saving of 15kg (81kg reduction in poured weight).

- Future developments planned to include additive manufacture of core segments and further use of protective coatings to increase service life.