Finecast Foundry Ltd have developed a gearbox consisting of 5 main castings and fragile internal cores (printed using cerabead to offer a more robust solution).

Component

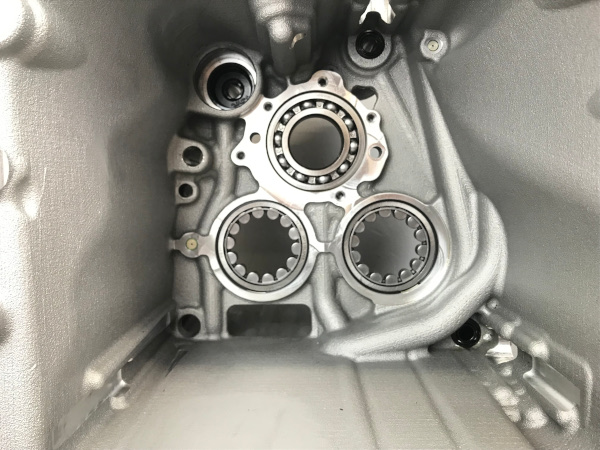

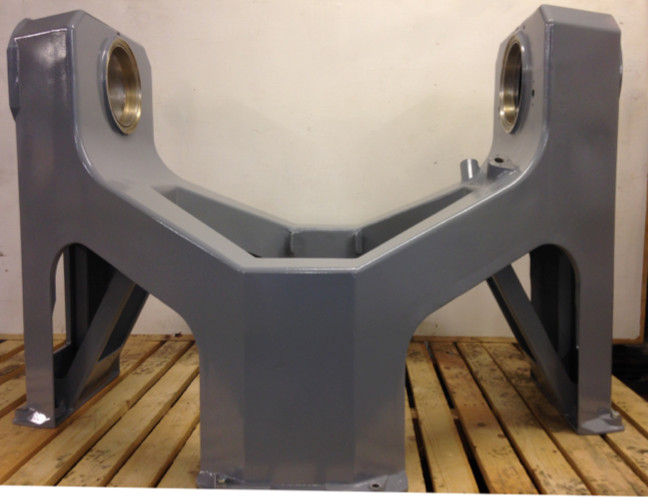

Gearbox assembly for the automotive sector, in A356 aluminium alloy, consisting of five main castings, each with very high dimensional tolerances.

Challenges

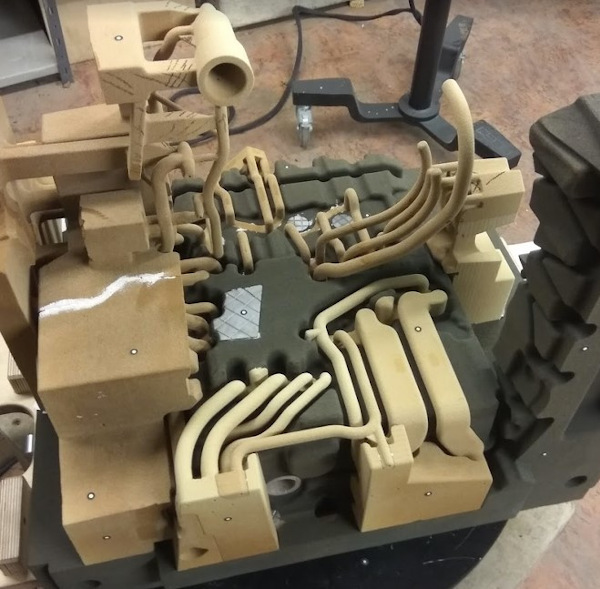

- Complex internal core geometry, with risks of gas being trapped during casting and core cracking.

- High internal core dimensional accuracy required.

- High casting integrity requirements.

- X-ray inspection: AMS STD 2175 Class 1 Grade C.

- Casting to resist leak testing confirmed by pressure testing to 20 Bar.

Method

- Close collaboration with customer to optimise design for casting with additional bosses to provide core support.

- Casting simulation used to confirm filling geometry, reduce liquid metal turbulence and optimise methoding design to reduce risk of shrinkage porosity.

- Chemically bonded sand casting used to produce casting mould.

- Cerabead cores used to reduce risk of core cracking during casting and optimise dimensional control.

- Cores design with small vents to reduce risk of gas entrainment.

- 3D printed cores to increase strength and steel guide pins employed to minimise assembly variability.

- GOM scanning of mould and core assembly prior to casting to ensure mould accuracy.

- HIPping of casting completed prior to pressure testing to 20 bar.

- Visual and full NDT inspection to ensure customer specification achieved.