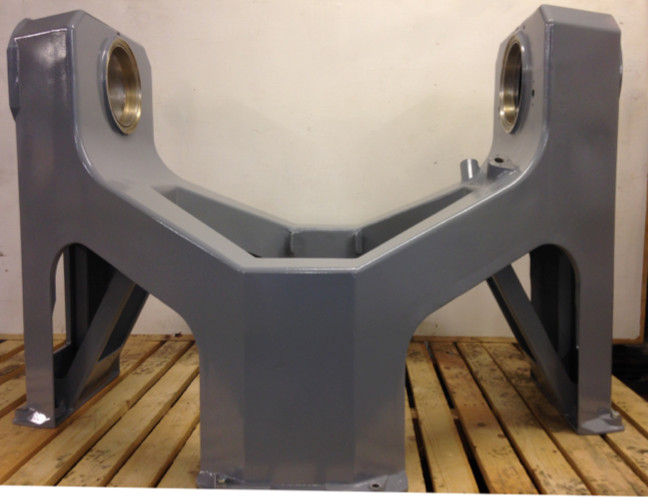

William Cook Rail cast the rail bolster for the Citadis Spirit Light Rail Vehicle.

Component

Bolster for Alston Citadis Spirit Light Rail Vehicle.

The castings were supplied for 118 trains, each with a steel bolster and half frames, plus other chassis components.

The client turned to William Cook Rail when the original USA supplier was unable to meet the quality requirements and leaving only 12 months from design to the first batch of castings.

Customer Requirements and Challenges

- Safety critical part with tight timescale for delivery.

- Casting to be supplied finish machined, painted and pressure tested.

- Porosity free castings and zero post-machining weld rectification permitted.

- CMM dimensional inspection required with a report stating 46 different dimensions.

- Very tight dimensional tolerances, to 30 microns.

Method

- Sand cast using chemically bonded sand moulds & cores.

- Casting method optimised using simulation of the filling and solidification cycle.

- Proof and finish machining processes developed in-house, using bespoke fixtures and processes optimised to meet customer timescales.

- MPI and ultrasonic inspection.

- Full CMM dimensional inspection

Outcome

118 castings were supplied to the customer enabling them to meet the requirement to supply light rail vehicles to two North American cities.